Value Stream Optimization: Create Breakthroughs through Visual Problem Solving

- Why Lean Management Matters

- 1. The Principle of Value

- 2. The Principle of Value Stream

- 3. The Principle of Flow

- 4. The Principle of Pull

- 5. The Principle of Perfection

- Lean Thinking: A Mindset for Success

- How to Implement Lean Principles in Your Organization?

- Conclusion: Transform Your Business with Lean Principles

- Key Takeaways

- FAQs

Value Stream: Visual Problem Solving to Turbocharge Your Business

1. What is a Value Stream?

A value stream is a series of activities that are required to deliver a specific product or service to customers.

It is the end-to-end process that includes all the steps and resources needed to bring value to the customer.

For example, in a manufacturing company, the value stream may start from the procurement of raw materials, go through the production process, and end with the delivery of the finished product to the customer.

It encompasses all the activities, people, and materials involved in creating and delivering the product or service.

The goal of analyzing and optimizing the value stream is to identify and eliminate any steps or resources that do not directly add value to the customer, thus increasing efficiency and improving customer satisfaction.

A value stream encompasses both the physical and informational flow of products or services. It starts with the sourcing of raw materials or the initiation of a service request and goes all the way to the customer receiving the final product or service.

Value streams can be found in various industries, such as manufacturing, healthcare, finance, and software development.

The purpose of identifying and analyzing a value stream is to understand and improve the flow of value to the customer.

By mapping out each step in the value stream, organizations can identify inefficiencies, bottlenecks, and areas for improvement. This can lead to reduced lead times, increased operational efficiency, and improved customer satisfaction.

Value stream mapping is a commonly used tool to visualize and analyze the current state of a value stream and identify opportunities for improvement.

Implementing a value stream approach requires collaboration and communication across all departments and functions involved in the value stream.

It involves breaking down silos and creating a cross-functional team that is responsible for managing the entire value stream.

Continuous improvement is a key aspect of a value stream approach, as organizations must continuously monitor and analyze their value streams to identify opportunities for further improvement.

Overall, a value stream is a critical concept that enables organizations to optimize their processes and deliver value efficiently to their customers.

By understanding the end-to-end flow of value, organizations can minimize waste, enhance productivity, and ultimately achieve competitive advantage.

2. A Brief History of Value Stream

Value stream is a concept that originated in the world of manufacturing and has since been applied to various industries and processes.

The term was first popularized by James Womack and Daniel Jones in their book, “Lean Thinking,” published in 1996.

However, the roots of value stream can be traced back even further to the Toyota Production System, which was developed in the 1940s by Taiichi Ohno and Shigeo Shingo.

The Toyota Production System introduced the concept of eliminating waste from the manufacturing process and focused on producing products based on customer demand.

This approach, known as just-in-time manufacturing, revolutionized the manufacturing industry and led to significant improvements in quality, efficiency, and cost-effectiveness.

It emphasized the importance of mapping out the entire value stream, which refers to all the steps and processes involved in creating and delivering a product or service.

By visualizing the value stream, companies can identify and eliminate non-value-added activities and reduce waste.

The value stream concept has since been adopted by various other industries, including healthcare, software development, and service industries.

Today, value stream mapping is a common tool used by organizations to identify and optimize their value streams.

It provides a visual representation of the flow of materials, information, and activities, helping companies identify bottlenecks, inefficiencies, and opportunities for improvement.

Value stream thinking has evolved from a manufacturing concept to a strategic tool that enables companies to improve their overall performance and deliver greater value to customers.

3. Why understanding Value Streams is important for any business?

Understanding value streams is crucial for any business because it enables organizations to identify and eliminate bottlenecks, streamline processes, and enhance overall efficiency.

A value stream represents the end-to-end activities that are required to deliver a product or service to a customer.

By mapping out the entire value stream, businesses gain a comprehensive understanding of all the steps involved, including those that add value and those that do not.

This knowledge empowers organizations to optimize their processes and focus their resources on activities that truly benefit the customer.

Identifying bottlenecks is one of the key benefits of understanding value streams. Bottlenecks are any activities or resources that slow down the flow of value and create delays or inefficiencies in the value stream.

By identifying and addressing these bottlenecks, businesses can streamline their operations and decrease lead times, ultimately improving customer satisfaction.

Moreover, understanding value streams allows organizations to eliminate non-value-added activities, such as unnecessary paperwork or redundant processes.

This streamlining of processes enables businesses to operate more efficiently, reducing waste and increasing productivity.

In addition to improving operational efficiency, understanding value streams also helps align business activities with customer expectations.

By focusing on the value-adding steps in the value stream, businesses can ensure that they are delivering products or services that meet customer needs and preferences.

This customer-centric approach enhances customer satisfaction and loyalty, ultimately contributing to the success and profitability of the business.

Overall, understanding value streams is essential for businesses to identify bottlenecks, streamline processes, and align their activities with customer expectations, leading to improved efficiency and increased customer satisfaction.

4. Understanding Value Streams: The Value Stream Mapping(VSM) Tool

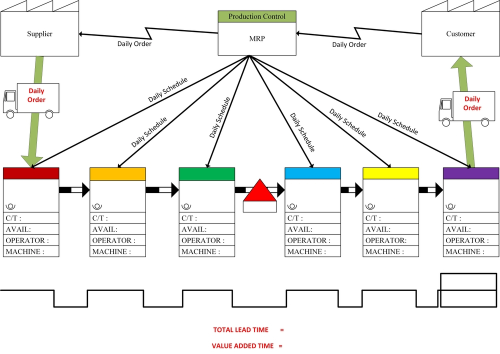

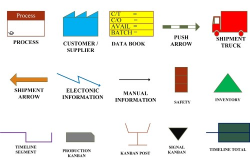

Value Stream Mapping (VSM) is a visual tool used to understand and analyze the flow of materials and information needed to deliver a product or service to a customer.

It provides a detailed map of the various processes involved in creating value and helps identify areas of waste and inefficiency.

By examining the entire value stream, from the initial raw materials to the final customer, organizations can gain insights into process bottlenecks, lead times, and opportunities for improvement.

VSM allows companies to see the big picture and understand the end-to-end flow of their operations, enabling them to make data-driven decisions and implement changes that eliminate waste, reduce costs, and improve overall performance.

By visualizing the value stream, teams can collaborate and identify opportunities to streamline processes, reduce cycle times, and enhance customer satisfaction.

Ultimately, VSM enables organizations to identify and focus on value-adding activities, thus driving operational excellence and delivering value to the customer.

What are the components of a Value Stream map?

A value stream is a series of steps and activities that are required to deliver a product or service to a customer.

It represents the end-to-end process, from the initial customer request or order to the final delivery. The components of a value stream typically include:

- Customer: The customer is the starting point of the value stream. They initiate the process by making a request, placing an order, or expressing a need for a product or service. Understanding the customer’s requirements and expectations is crucial to delivering value.

- Process Steps: These are the specific tasks and activities involved in fulfilling the customer’s request. Process steps may vary depending on the nature of the product or service but generally include design, production, assembly, testing, packaging, and distribution.

- Value-Adding Activities: Value-adding activities are those that directly contribute to meeting the customer’s needs and requirements. These activities add value to the product or service and are considered essential.

- Non-Value-Adding Activities (Waste): Non-value-adding activities, also known as waste, are tasks or steps that do not contribute to meeting customer needs and requirements. Identifying and eliminating waste is a key objective of value stream mapping.

- Information Flow: Information flow includes all the data and communication required to support the value stream. This can involve order processing, scheduling, inventory tracking, and other information-related activities.

- Materials Flow: Materials flow represents the physical movement of materials, components, and products through the value stream. This includes the sourcing of raw materials, transportation, processing, and storage.

- Work in Progress (WIP) Inventory: WIP inventory is the inventory that is in various stages of completion within the value stream. Excessive WIP can lead to increased lead times and waste.

- Lead Time: Lead time is the total time it takes to complete the entire value stream, from the customer’s initial request to the final delivery. It encompasses all process steps, waiting times, and delays.

- Metrics and Key Performance Indicators (KPIs): To measure the performance of the value stream, organizations establish metrics and KPIs. These may include cycle time, on-time delivery, defect rates, and customer satisfaction scores.

- Resources: Resources encompass the people, machines, tools, and equipment required to perform the process steps. Efficient allocation and utilization of resources are essential for optimizing the value stream.

- Bottlenecks and Constraints: Bottlenecks are points in the value stream where work accumulates, causing delays and inefficiencies. Identifying and addressing bottlenecks is crucial for improving flow.

- Supporting Functions: In addition to the core process steps, there are often supporting functions such as maintenance, quality control, and engineering that play a role in the value stream.

- Feedback Loops: Feedback loops represent mechanisms for collecting feedback from customers, monitoring process performance, and making continuous improvements to the value stream.

- Customer Satisfaction and Requirements: The value stream must be aligned with customer requirements and should aim to deliver products or services that meet or exceed customer expectations.

These components collectively define the value stream and provide a comprehensive view of how value is created and delivered to the customer.

Value stream mapping involves analyzing each of these components to identify opportunities for improvement and waste reduction.

By optimizing the value stream, organizations can enhance their ability to deliver value more efficiently and effectively to their customers.

How does value stream mapping help in delivering value to the customer?

Value stream mapping is a lean management technique that helps organizations visualize and analyze the steps and processes involved in delivering a product or service to a customer.

It is a powerful tool for identifying and eliminating waste, optimizing processes, and ultimately delivering more value to the customer.

Here’s how value stream mapping helps in delivering value to the customer:

- Visualization of the Value Stream: Value stream mapping provides a visual representation of the end-to-end process involved in delivering a product or service. This map includes all the steps, activities, and resources required, from the initial customer request to the final delivery.

- Identification of Waste: By mapping out the entire value stream, organizations can identify and categorize different types of waste, such as overproduction, unnecessary waiting, defects, and excessive inventory. This waste can be targeted for elimination, which streamlines processes and reduces costs.

- Process Analysis: Value stream mapping allows organizations to analyze each step in the value stream in detail. Teams can identify bottlenecks, delays, and inefficiencies in the process.This analysis enables them to make data-driven decisions to improve the flow of work and eliminate obstacles that hinder value delivery.

- Customer Focus: Value stream mapping emphasizes the importance of customer value. It helps organizations understand the specific activities that directly contribute to meeting customer needs and those that do not. This customer-centric approach ensures that resources are allocated to activities that matter most to customers.

- Streamlined Workflows: Through the mapping process, teams can redesign and optimize workflows to reduce lead times and increase efficiency. This can involve resequencing tasks, changing the allocation of resources, or eliminating non-value-added activities.

- Standardization and Continuous Improvement: Value stream mapping encourages the standardization of processes and the establishment of key performance indicators (KPIs) to measure progress. Once improvements are implemented, the map can be updated to reflect the new, optimized state, and the cycle of continuous improvement continues.

- Cross-Functional Collaboration: Value stream mapping often involves cross-functional teams that collaborate to understand the end-to-end process. This collaboration fosters a shared understanding of how different functions contribute to value delivery and encourages problem-solving and communication across departments.

- Cost Reduction: By eliminating waste, reducing lead times, and improving resource utilization, organizations can significantly reduce their operational costs. These cost savings can be reinvested into value-adding activities or passed on to customers through lower prices.

- Quality Improvement: Value stream mapping helps identify areas where defects or errors may occur in the process. By addressing these issues, organizations can improve product or service quality, leading to higher customer satisfaction.

- Faster Delivery: Streamlined processes and reduced lead times mean that organizations can deliver products or services to customers more quickly. This can be a significant competitive advantage in today’s fast-paced business environment.

What are common misconceptions in Value Stream Mapping?

There are several common misconceptions associated with value stream mapping that can hinder its effectiveness.

- It’s Just About Drawing Maps: One common misconception is that value stream mapping is primarily a drawing exercise. While creating visual maps is a key aspect of the process, the real value lies in the analysis, problem-solving, and process improvement that come from the mapping exercise. Simply drawing a map without deeper analysis and action won’t yield significant benefits.

- It’s Only for Manufacturing: While value stream mapping originated in manufacturing, it can be applied to various industries and processes, including healthcare, service industries, and software development. Some believe it’s only relevant in manufacturing, which limits its application in other sectors.

- It’s a One-Time Activity: Some organizations view value stream mapping as a one-time event, often done as a project or initiative. However, value stream improvement should be an ongoing and continuous process. Processes change over time, and value stream mapping should evolve to reflect these changes.

- It’s a Quick Fix: Value stream mapping can uncover opportunities for improvement, but it doesn’t guarantee instant fixes. Implementing changes and improvements often takes time, effort, and sustained commitment. Some expect immediate results and become disillusioned when they don’t see rapid improvements.

- It’s Solely a Lean Tool: While value stream mapping is closely associated with Lean principles, it can be used in conjunction with other process improvement methodologies, such as Six Sigma or Agile. Some mistakenly believe that it’s exclusively for Lean initiatives.

- It’s Just for Operational Efficiency: While operational efficiency is a common goal of value stream mapping, it’s not its only purpose. It can also help organizations focus on customer value, quality improvement, and aligning processes with strategic objectives.

- It’s a Top-Down Approach Only: Value stream mapping is often initiated by management, but it’s most effective when it involves cross-functional teams that include employees who work directly on the processes being mapped. Some believe it’s solely a top-down management tool.

- It Requires Complex Software: While there are software tools available for value stream mapping, it can also be done effectively with pen and paper or whiteboards. Using complex software isn’t a requirement, and simplicity in mapping can sometimes be more effective.

- It’s About Eliminating All Waste: While the goal is to eliminate waste, not all waste can be eliminated entirely. Some waste is inherent to certain processes, and it’s essential to strike a balance between waste reduction and maintaining process stability.

- It’s Only for Large Organizations: Value stream mapping can benefit organizations of all sizes, including small businesses. Smaller organizations sometimes believe it’s too complex or time-consuming for their scale, but it can be adapted to fit their needs.

In summary, value stream mapping is a valuable tool when used correctly, but it’s essential to dispel these common misconceptions to maximize its effectiveness.

It’s not just about drawing maps; it’s a holistic approach to improving processes and delivering more value to customers.

5. What are the types of Value Streams?

Value streams can be categorized into several types based on the nature of the products or services being delivered, the industry, and the specific goals of the organization.

Here are some common types of value streams:

- Production Value Stream: This type of value stream is typical in manufacturing industries. It encompasses all the steps and processes involved in producing physical goods. It starts with the receipt of raw materials and ends with the delivery of finished products to customers.

- Service Value Stream: Service value streams focus on delivering services rather than physical products. They include activities such as customer support, IT services, healthcare services, and financial services. The goal is to provide valuable services efficiently and effectively.

- Supply Chain Value Stream: Supply chain value streams involve the movement of goods and materials from suppliers to customers. This type of value stream often spans multiple organizations and includes processes like procurement, transportation, warehousing, and distribution.

- Software Development Value Stream: Development value streams are common in software development and product development. They encompass the steps involved in designing, developing, testing, and releasing new products or software applications. Agile and DevOps methodologies are often used in development value streams.

- Order Fulfillment Value Stream: Order fulfillment value streams focus on the process of receiving and processing customer orders, picking and packing products, and delivering them to customers. It is commonly found in retail, e-commerce, and distribution industries.

- Custom Value Stream: Some organizations define custom value streams tailored to their unique products or services. These value streams are designed to meet the specific needs and requirements of the organization and its customers.

- Continuous Improvement Value Stream: This type of value stream is focused primarily on the continuous improvement of existing processes. It involves regular review and optimization of processes to eliminate waste and enhance efficiency.

- New Product Introduction (NPI) Value Stream: NPI value streams are dedicated to the introduction of new products into the market. They encompass the product development process, including design, prototyping, testing, and market launch.

- Customer Journey Value Stream: Customer journey value streams map out the customer’s experience from the moment they express a need or interest to the point of purchase and beyond. It helps organizations understand and improve the customer experience.

- Supplier Value Stream: This type of value stream focuses on the processes related to managing and collaborating with suppliers. It includes supplier selection, order placement, quality assurance, and supplier performance evaluation.

- Maintenance and Repair Value Stream: Maintenance and repair value streams involve activities related to the maintenance, repair, and servicing of equipment, machinery, or infrastructure. It ensures that assets remain operational and reliable.

The specific types of value streams in an organization may vary depending on its industry, size, and goals.

Organizations often use value stream mapping and analysis to identify and define the most relevant and critical value streams for their business.

Each type of value stream requires its own set of strategies and approaches to optimize processes and deliver value to customers efficiently.

6. How to map your Value Stream?

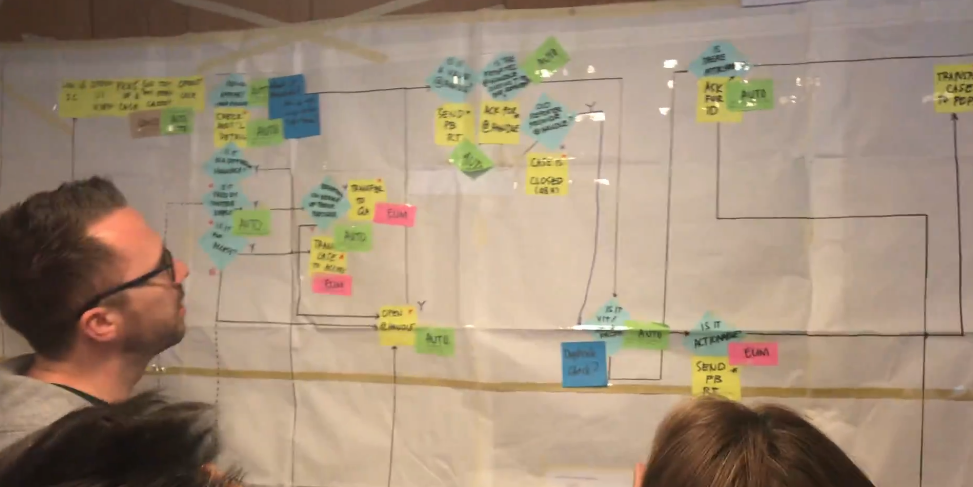

Mapping a value stream requires a structured approach. The below steps outline such an approach that True North Solutions follows with its clients. It always starts with understanding the ‘Why’ before embarking on the actual mapping exercise.

Understanding the ‘Why’ of Mapping the Value Stream

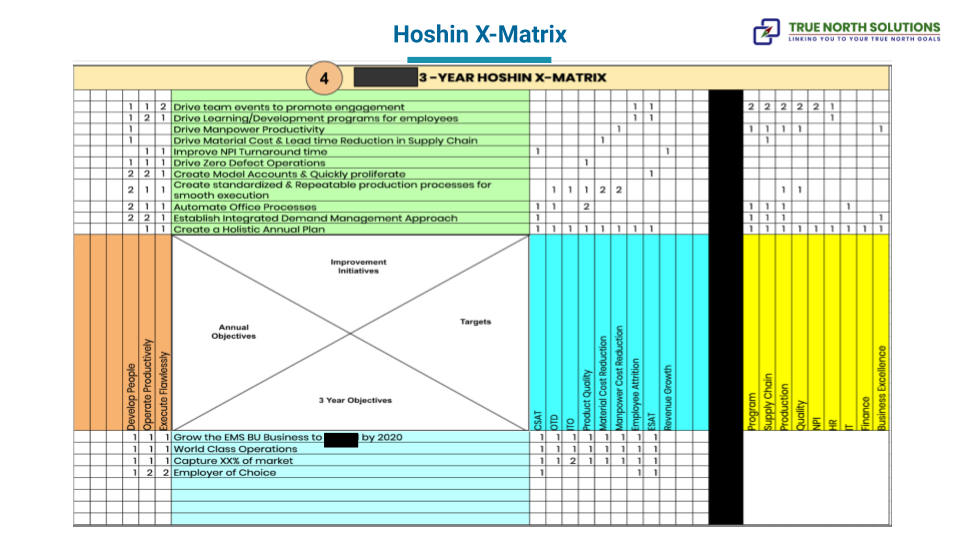

In the world of strategic planning and continuous improvement, Hoshin Kanri is a powerful framework that aligns an organization’s top leadership with its operational teams.

Before diving into a formal value stream mapping exercise as part of Hoshin Kanri, it’s crucial for top leadership to establish a clear understanding of the “why” behind this endeavor.

This understanding serves as the compass that guides the organization toward achieving its strategic goals.

Here’s a step-by-step practical list, along with examples, for top leadership to consider before teams proceed with a value stream mapping exercise:

Step 1: Clarify Strategic Objectives:

Start by revisiting your organization’s strategic objectives as established through the strategy deployment exercise conducted using the Hoshin Kanri methods.

What are the overarching goals you aim to achieve?

Be specific about the outcomes you expect from value stream mapping in the context of these objectives.

For example, this could be one of the objectives: Increase customer satisfaction by reducing lead times for product delivery by 20% within the next year.

Or if an organization’s strategic objective is to increase market share, leadership might focus the value stream mapping exercise on identifying opportunities to reduce lead times and enhance product quality to better compete in the market.

Step 2: Identify Key Performance Indicators (KPIs)

Select KPIs that align with the strategic goals.

These metrics will help measure progress and success in achieving the objectives. For instance:KPI: Average lead time for product delivery.

Step 3: Communicate the Purpose

Clearly communicate the purpose of value stream mapping to the teams.

Explain how it ties into the broader strategic objectives. Use a simple, concise message like:

“We’re embarking on value stream mapping to streamline our processes and reduce lead times. This directly supports our goal of enhancing customer satisfaction.”

Step 4: Define the Scope

Specify which value stream(s) will be mapped and improved. Ensure that these align with the strategic priorities.

For example:

Scope: Value stream mapping will initially focus on the order-to-delivery process for our flagship product line, as this directly impacts our customer satisfaction target.

Step 5: Set Expectations

Clearly outline what the leadership team expects to achieve from value stream mapping. Be specific about the anticipated outcomes. For instance: “We expect value stream mapping to reveal opportunities for reducing waste, optimizing workflows, and achieving a 20% reduction in lead times within the next year.”

Step 6: Establish a Continuous Improvement Culture

Emphasize that value stream mapping is not a one-time effort but part of an ongoing commitment to continuous improvement.

Encourage teams to embrace a culture of continuous learning and problem-solving.

Step 7: Provide Resources and Support

Ensure that teams have the necessary resources, tools, and support to carry out value stream mapping effectively.

This might include training in Lean principles or access to process mapping software.

An experienced Lean consultant is appointed to facilitate the value stream mapping exercise, guiding the team through the process and ensuring that Lean principles are effectively applied.

Step 8: Encourage Cross-Functional Collaboration

Highlight the importance of cross-functional collaboration.

Teams from different departments should work together to map the value stream, fostering a shared understanding of the end-to-end process.

Step 9: Share Success Stories

Share examples of organizations that have successfully used value stream mapping to achieve similar goals.

These success stories can inspire and motivate teams.

Step 10: Emphasize the Impact on Customers

Reiterate how the outcomes of value stream mapping will directly impact customers.

Use customer feedback or testimonials to emphasize the importance of improving customer satisfaction.

By following these practical steps, top leadership can lay the foundation for a successful value stream mapping exercise within the framework of Hoshin Kanri.

They provide teams with a clear understanding of the strategic context, the objectives to be achieved, and the significance of their efforts in improving processes and delivering value to customers.

How to map the Value Stream?

Before embarking on the journey of value stream mapping, it’s essential to lay the groundwork for a successful exercise.

The preparation stage sets the stage for a structured and effective value stream mapping process.

1. Preparation Stage

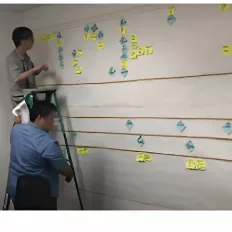

1.1 Form a Team to Create the Lean Value Stream Map

- Team Composition: Assemble a cross-functional team comprising individuals from various departments or functions involved in the value stream.

- This diverse group brings different perspectives and expertise to the table.

- Team Leader: Appoint a team leader or facilitator responsible for guiding the mapping process, ensuring that it stays on track, and fostering collaboration among team members.

- Team Training: Ensure that team members understand the principles of Lean and value stream mapping. Provide any necessary training or resources to equip them for the task.

1.2 The Kaizen Kick-Off – VSM Planning

- Kick-off Meeting: Initiate the value stream mapping process with a kick-off meeting. During this meeting, communicate the purpose, goals, and expected outcomes of the mapping exercise.

- Set Objectives: Clearly define the objectives you aim to achieve through value stream mapping. These objectives should align with your organization’s broader strategic goals.

- Plan the Schedule: Establish a timeline and schedule for the value stream mapping exercise. Ensure that all team members are aware of the time commitment required.

1.3 The Process Family – VSM Planning

- Identify Process Families: Categorize your processes into “process families” based on their similarities and interactions. This step helps in organizing the mapping effort effectively.

- Select the Value Stream: Choose the specific value stream you intend to map. This decision should align with your strategic objectives and the identified process families.

- Define Boundaries: Clearly define the scope and boundaries of the value stream you’ll be mapping. This ensures that the team focuses on the relevant processes.

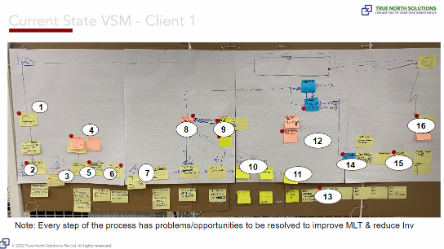

2. Map the Current State

Once the preparation stage is complete, it’s time to dive into the actual mapping process. This stage involves creating a visual representation of your existing processes to gain a clear understanding of the current state.

- Gather Data: Collect relevant data and information about the processes within the value stream. This may include cycle times, lead times, inventory levels, and other performance metrics.

- Create a Current State Map: Use value stream mapping symbols and techniques to create a visual representation of the current state. Highlight each step, including value-adding and non-value-adding activities.

- Identify Waste: During the current state mapping, identify and label instances of waste (such as overproduction, waiting, or excessive inventory). These will be key areas for improvement.

3. Map the Ideal State

With a clear understanding of the current state, you can now envision an ideal state for your value stream.

This stage focuses on designing a more efficient and streamlined process.

- Eliminate Waste: Identify opportunities to eliminate waste and inefficiencies from the current state. Determine how processes can be optimized for better flow and reduced lead times.

- Create an Ideal State Map: Use value stream mapping techniques to create a visual representation of the ideal state. This map should reflect the improved processes and reduced waste.

- Set Performance Metrics: Define key performance indicators (KPIs) for the ideal state. These metrics will help measure progress and success as you work toward this state.

4. Map the Future ‘Interim’ State

In many cases, achieving the ideal state may take time and multiple improvement cycles. Therefore, it’s important to map an interim state that represents a significant improvement from the current state.

- Identify Incremental Changes: Determine the specific changes and improvements that can be implemented in the short term to move closer to the ideal state.

- Create an Interim State Map: Use value stream mapping techniques to create a visual representation of the interim state. This map should reflect the changes and improvements planned for the near future.

- Set Short-Term Goals: Define short-term goals and milestones for achieving the interim state. These goals should be achievable within a relatively short time frame.

5. Implementation Roadmap

Now that you have mapped the current state, ideal state, and interim state, it’s time to develop a roadmap for implementing the necessary changes and improvements.

- Prioritize Improvement Opportunities: Based on your mapping exercises, prioritize the improvement opportunities and initiatives that will move you closer to the ideal state.

- Assign Responsibilities: Identify individuals or teams responsible for implementing each improvement initiative. Clearly define roles and responsibilities.

- Establish Timelines: Create a timeline for each improvement initiative, outlining when it will be initiated, its expected duration, and completion date.

- Allocate Resources: Ensure that the necessary resources, including budget, personnel, and technology, are allocated to support the implementation of improvement initiatives.

6. Governance Structure/Cadence

To ensure the sustained success of your value stream improvement efforts, establish a governance structure and cadence for regular review and monitoring.

- Governance Committee: Form a governance committee comprising senior leaders and key stakeholders. This committee will oversee and guide the implementation of improvement initiatives.

- Regular Reviews: Schedule regular reviews and checkpoints to assess the progress of improvement initiatives, track KPIs, and make necessary adjustments.

- Feedback Loops: Establish feedback loops that allow team members and stakeholders to provide input, share insights, and suggest improvements throughout the implementation process.

By following these steps, you can systematically map your value stream, set a clear direction for improvement, and develop a roadmap for achieving your desired state of efficiency and value delivery.

Remember that value stream mapping is not a one-time event; it’s an ongoing process of continuous improvement and optimization.

7. Value Stream Mapping Applications

Value stream mapping is a versatile tool that finds applications across various industries and sectors.

Its adaptability allows organizations to identify and eliminate inefficiencies, optimize processes, and deliver greater value to customers.

In this section, we explore the applications of value stream mapping in manufacturing, service industries, knowledge work, development value streams, and specifically within the realm of software development.

Value Streams in Manufacturing

Manufacturing industries were the early adopters of value stream mapping, and its applications in this sector remain prominent:

- Production Efficiency: Value stream mapping helps identify bottlenecks and waste in manufacturing processes, allowing for streamlined operations, reduced lead times, and increased production efficiency.

- Inventory Management: By mapping value streams, organizations can optimize inventory management, reducing excess inventory and associated carrying costs while ensuring just-in-time supply.

- Quality Improvement: Identifying defects and non-value-adding activities within the value stream enables organizations to implement quality improvement measures and enhance product quality.

Value Streams in Service Industry

Value stream mapping extends beyond manufacturing and is widely applied in the service industry:

- Customer Experience Enhancement: Mapping service value streams helps organizations understand the end-to-end customer journey, enabling them to improve customer experience by minimizing delays and inefficiencies.

- Process Standardization: Service providers use value stream mapping to standardize processes, ensuring consistent service delivery and reducing variations.

- Cost Reduction: In the service sector, value stream mapping aids in identifying areas where cost reduction is possible by eliminating waste, improving resource allocation, and reducing lead times.

Value Streams in Knowledge Work

Value stream mapping is also applicable in knowledge work environments, where work is often intangible and information-based:

- Process Visualization: Knowledge workers can use value stream mapping to visualize complex processes, making it easier to identify areas for improvement and efficiency gains.

- Workflow Optimization: Value stream mapping enables knowledge workers to streamline their workflows, reducing lead times for tasks such as content creation, project management, or research.

- Reducing Overhead: In knowledge work, mapping value streams can help identify unnecessary administrative tasks and reduce overhead, freeing up time for more value-adding activities.

- Value streams in software development: Within the broader context of development value streams, software development holds a unique place:

- Agile and DevOps Alignment: Value stream mapping in software development helps align Agile and DevOps methodologies, ensuring a smooth and continuous delivery pipeline.

- Cycle Time Reduction: Identifying and eliminating bottlenecks in the software development value stream accelerates cycle times, enabling faster release of software updates and enhancements.

- Quality Assurance: Value stream mapping allows software development teams to focus on quality assurance activities by reducing time wasted on rework and defect resolution.

8. Challenges in Mapping the Value Stream

While value stream mapping offers numerous benefits, it also comes with certain challenges that organizations need to address:

Complexity

Mapping complex value streams, especially in large organizations with intricate processes, can be challenging. It may require significant time and effort to create accurate and comprehensive maps.

Resistance to Change

Some team members or departments may resist changes to existing processes, viewing them as disruptive or unnecessary. Overcoming resistance can be a challenge.

Data Availability

Gathering accurate and up-to-date data for value stream mapping can be a challenge. Incomplete or inaccurate data can lead to suboptimal decisions.

Lack of Expertise

Effective value stream mapping requires knowledge and expertise in Lean principles and mapping techniques. Organizations may need to invest in training to ensure their teams can perform mapping effectively.

Resource Constraints

Implementing improvement initiatives identified through value stream mapping may require additional resources, which can strain budgets and capacity.

Maintaining Momentum

Organizations may find it challenging to maintain the momentum of continuous improvement efforts over the long term. It’s essential to establish a structured approach for sustaining improvements.

Overlooking External Factors

Value stream mapping often focuses on internal processes, potentially overlooking external factors that can impact value streams, such as changes in market conditions or disruptions in the supply chain.

Measurement and KPI Selection

Selecting the right key performance indicators (KPIs) and measuring progress can be challenging. In some cases, organizations may struggle to quantify the impact of improvements accurately.

Balancing Short-Term and Long-Term Goals

Organizations must strike a balance between addressing immediate issues and focusing on longer-term strategic goals when implementing value stream improvements.

While value stream mapping offers significant benefits in terms of process optimization and efficiency, organizations should be aware of the potential challenges and take proactive steps to address them.

With the right approach and commitment to continuous improvement, the benefits of value stream mapping can outweigh the challenges, leading to enhanced performance and customer satisfaction.

We at True North Solutions, with our many years of experience in diverse industries and companies, can help our clients avoid the pitfalls to ensure speed and effectiveness in realizing the objectives that could be achieved using Value Stream Optimization methods.

FAQs

1. What is a value stream?

A value stream is the sequence of activities that are required to create and deliver value to the customer. It encompasses all the steps, processes, and resources involved in the production and delivery of a product or service.

2. What is a value stream map?

A value stream map (VSM) is a visual representation of the value stream, including all the processes, activities, and flows of both information and materials. It provides a comprehensive view of the current state of the value stream and helps identify areas of waste and opportunities for improvement.

3. How does visual problem-solving turbocharge a business?

Visual problem-solving is a key aspect of lean thinking and continuous improvement. By visually representing the value stream and identifying problem areas, teams can effectively collaborate and find solutions to eliminate waste, improve efficiency, and ultimately turbocharge the overall business performance.

4. How does agile relate to value stream?

Agile is an approach to project management that emphasizes flexibility, collaboration, and frequent iterations. It can be applied to value streams, particularly in the software development context, to ensure that customer feedback and changing requirements are incorporated throughout the value delivery process.

5. How does a value stream add value to a product or service?

A value stream focuses on identifying and eliminating activities that do not add value to the customer. By streamlining processes, reducing waste, and improving flow, a value stream can enhance the quality, speed, and overall value of the final product or service.

6. What is the role of the Lean Enterprise Institute in value stream management?

The Lean Enterprise Institute is a non-profit organization that is dedicated to promoting lean thinking and continuous improvement. They provide resources, training, and expertise in value stream management, helping organizations optimize their value streams and achieve operational excellence.

7. What is the difference between the current state and future state in value stream mapping?

The current state in value stream mapping refers to the existing state of the value stream, including all the processes, flows, and performance metrics. The future state, on the other hand, represents the desired state that an organization aims to achieve by eliminating waste, improving efficiency, and enhancing value delivery.

8. Who are the stakeholders in a value stream?

The stakeholders in a value stream include anyone who is directly or indirectly affected by the value delivery process. This can include customers, suppliers, employees, managers, and executives, among others. Effective stakeholder engagement is crucial for value stream optimization and problem-solving.